ChrisAll Solution handled Immudex's move to a new location, and the laboratory was up and running seven days later

Researcher, Amir Ameri, Immudex ApS, by the big freezers that store priceless material. The temperature in the freezers is minus 80°C. ‘If the temperature gets too high during the move, the material is destroyed, and that would mean a huge loss for the company. ChrisAll Solution planned everything very thoroughly and took the necessary precautions, so everything went smoothly,’ says Amir.

‘It was a really good experience for us,’ says Amir Ameri, the researcher responsible for the R&D laboratory at Immudex ApS, continuing: ‘The relocation of our three big freezers was absolutely critical to us. This is where we store material that’s incredibly important to the company. The error most likely to occur during the move is a rise in temperature caused by the transport and handling, etc. With a standard temperature of minus 80°C inside the freezers and about plus 10°C outside, maintaining the internal freezer temperature is somewhat of a challenge. But ChrisAll Solution planned the entire moving process in great detail and carried it out so there was no danger of our material being damaged.’

Meticulous planning

Jesper Berthelsen, CEO of ChrisAll Solution, explains: ‘When we move laboratories and technical equipment, we plan every step of the process down to the last detail – what are the access roads like from the premises to the lorry, how exactly do we access the new premises where we have to be able to install everything immediately. We have to consider any surprises and challenges that might arise, accounting for them in our planning and step-by-step preview of the route, and not during the move itself. That’s also why we require that our customer’s managers and staff are involved, so we can draw minutely on their extensive expertise to understand what’s important to them and their equipment or products. Nothing must be destroyed; everything must be correctly positioned as fast as possible. It’s not just a matter of moving a bunch of boxes from A to B.’

Production re-established after seven days

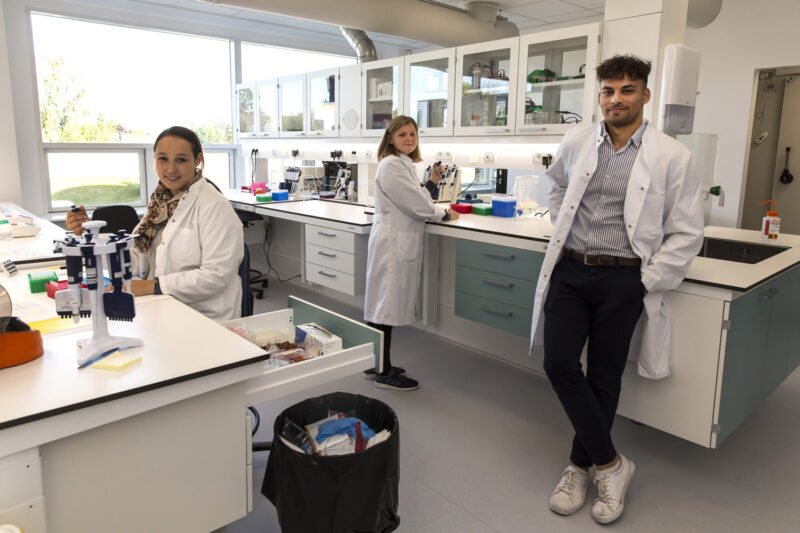

‘Actually, we’d in no way expected the laboratories to be up and running so quickly,’ says Amir. ‘It only took seven days! We’d numbered every single item of equipment to be moved, matching it with an identical reference number that we put on the tabletop, floor or walls, so the removal people knew exactly where to put the equipment and install it.’

Researcher Amir Ameri with colleagues in a section of the laboratory. ‘Our laboratory was operational just seven days after the move. We were surprised the process was so swift and trouble-free,’ he says.

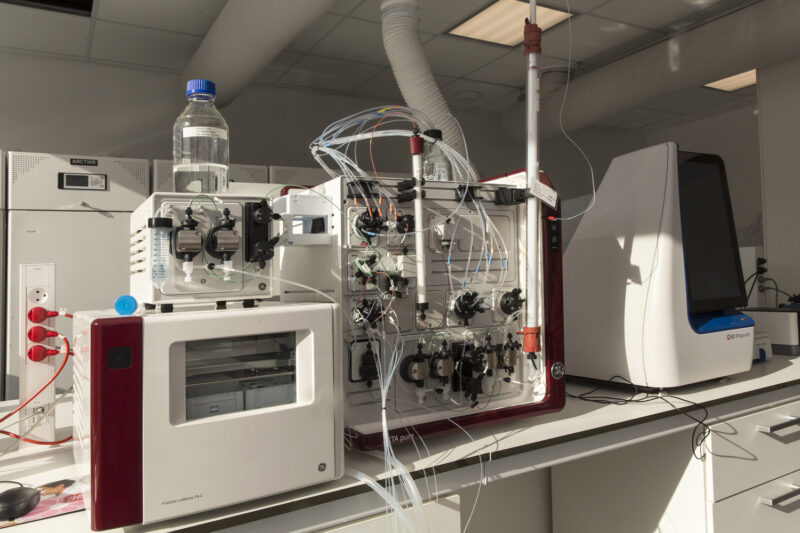

‘Some equipment is sensitive to vibration, and we were concerned about that,’ says Amir. ‘But with ChrisAll Solution’s special gear for that sort of task, there were no problems, and it was up and running with no trouble.’

‘When you have to move to a new location, a few irritating minor things usually go missing. They may only be trifles, but they delay the start-up. We had some special tables for some rather heavy scanners, and the fittings for some fluid reservoirs were missing. ChrisAll Solution spotted this, and even though it had nothing to do with the removal job as such, ChrisAll Solution also remedied it with fittings of the right quality,’ says Amir.

Some of the laboratory equipment that ChrisAll Solution moved for Immudex included delicate chromatography equipment, which cannot tolerate vibrations and whose tubing, for example, can be easily damaged if mishandled. ChrisAll Solution also moved this without a hitch, and provided turnkey service by moving and re-establishing both laboratories and offices.

Turnkey solution for Immudex

The Immudex ApS move involved the entire company, offices and laboratories alike. ChrisAll Solution also moved the offices as part of the turnkey solution. Every component of an office was installed at the relevant employee’s specific workstation, adjustable-height desks connected and so on. Immudex decided to pack and later connect its IT equipment itself, while in other cases ChrisAll Solution takes care of everything from packing to securing offices and computers, which are tested and can be used at once. Each solution is tailored to the customer’s needs.

About Immudex ApS

Immudex ApS produces MHC Dextramer® reagents that are used to quantify and sort antigen-specific T-cells in life science research and in-vitro diagnostics as well as to develop immunotherapies and vaccines.

Established in 2009, Immudex was originally a spin-off from the diagnostic company DAKO. The company’s head office, where its research, development, production and sales operations are based, relocated in the summer of 2020 from Symbion in Copenhagen to Hirschsprunghus in Virum.

Amir Ameri, Immudex ApS

About ChrisAll Solution:

ChrisAll Solution specializes in the relocation and re-establishment of laboratories, technical and scientific equipment, chemical and biological materials in the pharmaceutical industry, biotech, hospitals and universities. You can read more about ChrisAll Solution via this link: https://www.chrisall-solution.dk/